Explaining sensor Glass Corrosion On leica, blackmagic, and other cameras

Written by Justin Pfeiffer

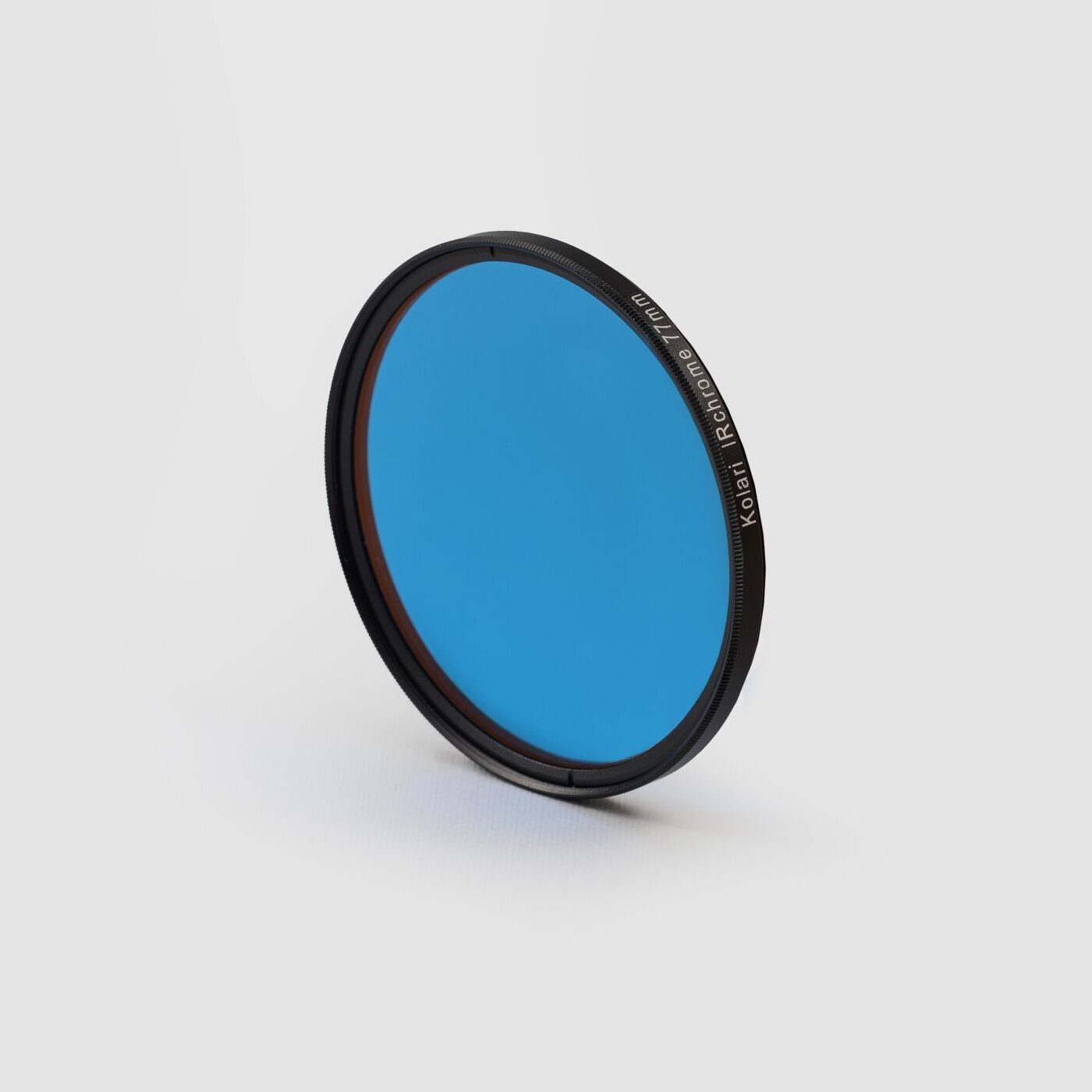

If you are a photographer or a filmmaker, you might be familiar with glass corrosion on certain blue/green filters, which is often mistaken for fungus. Specifically Leica and Blackmagic sensor glass often has issues with corrosion. In this video, we will break down the science behind why glass corrodes, how corrosion can be minimized, and the services we currently offer that address corrosion.

How Glass Corrodes

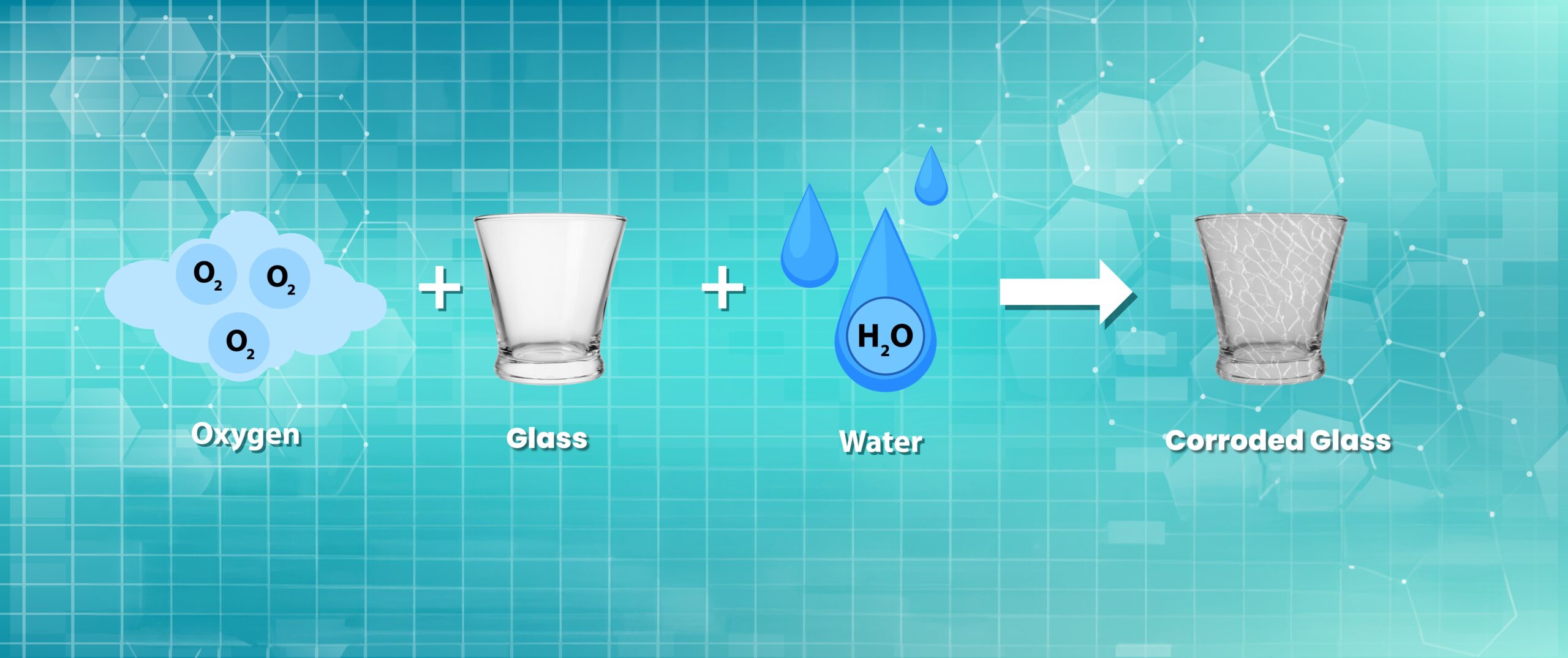

The easiest way to visualize how glass corrodes is to think about how steel rusts. When kept in a dry controlled environment, steel can last many years without any rust. If Zinc coatings are applied to the steel it can last even longer. But when steel is exposed to water or humid environments, the oxygen atoms from the air bond with the iron atoms to create Iron Oxide, also known as rust. A similar process happens to glass when exposed to water or high humidity. This is because glass is an amorphous solid structure that can absorb water. Ion in the glass react with oxygen in the atmosphere and water acts as the catalyst that expedites the corrosion process. Microscopic pitting of the surface occurs during the earliest stages of glass corrosion. If the reaction continues, damage on the surface will become more noticeable. Glass will become discolored and lose clarity.

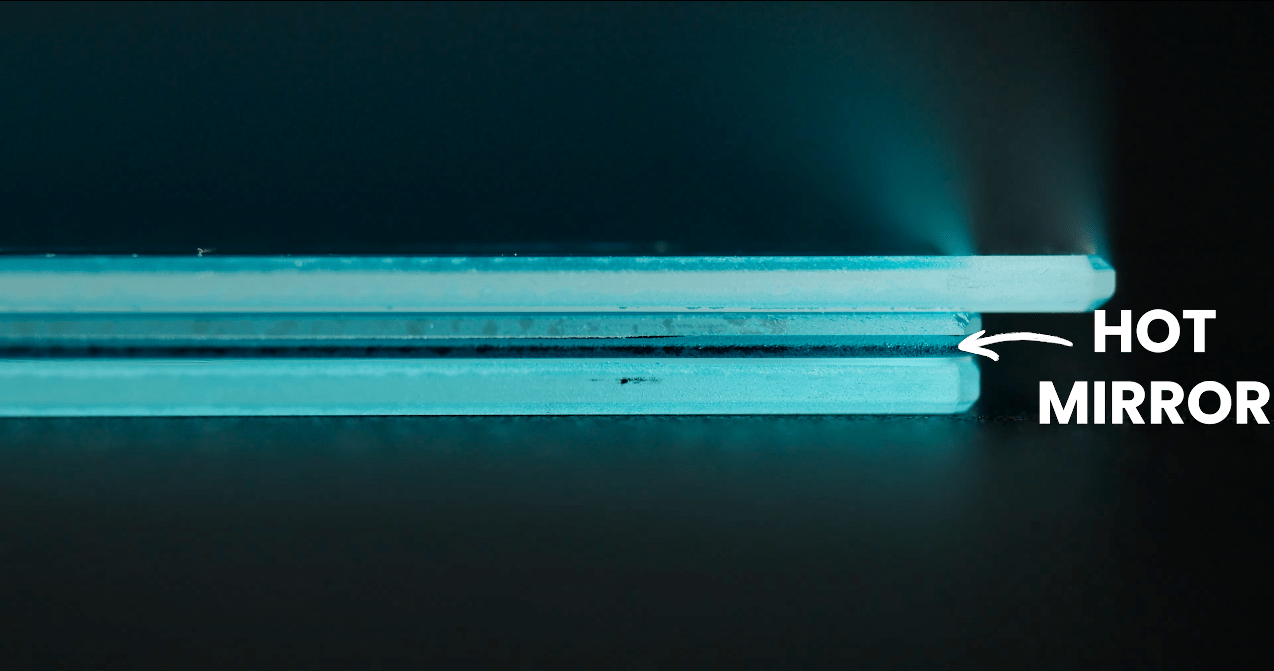

This becomes a huge issue when we are talking about using glass for imaging. All modern digital cameras have an internal filter that blocks infrared light called a “hot mirror” which is often a blue/green color. The problem is the blue/green pigment of the glass is the most prone to oxidizing and corroding. The Leica M9 is infamous for issues with hot mirror glass corrosion and many Blackmagic cameras experience the same issues. Leica allegedly used an older S8612 glass (and later the BG55), chosen for its high transmission at a thin thickness, and while this glass is coated, it failed to protect this glass sufficiently to prevent oxidation. If you lived in a humid area, you probably had issues quickly with the first cases being reported after about 5 years, while many cameras in a drier area the glass lasted much longer until the first signs appeared.

Preventing Corrosion

Once glass corrodes, the best way to fix it is to polish out the surface layer and reapply the coatings. However, it is much easier to simply prevent corrosion in the first place which can be done in several ways. The first method is to seal the glass with specialized coatings, similar to how zinc coatings are used to protect steel from rusting. Applying layers of oxygen-resistant coatings prevents the glass from undergoing the corrosive process. Coated glass can start to fail between 2-5 years depending on the environment, but can also last for decades. For example the Nikon D70 is 20 years old and we haven’t seen any issues with sensor glass corrosion. When done correctly, coated glass should last a very long time but sometimes, we see coatings fail much quicker whether that is due to the wrong type of coatings, not enough layers, or durability issues. Uncoated glass can wear down in as soon as 6-12 months depending on your humidity levels.

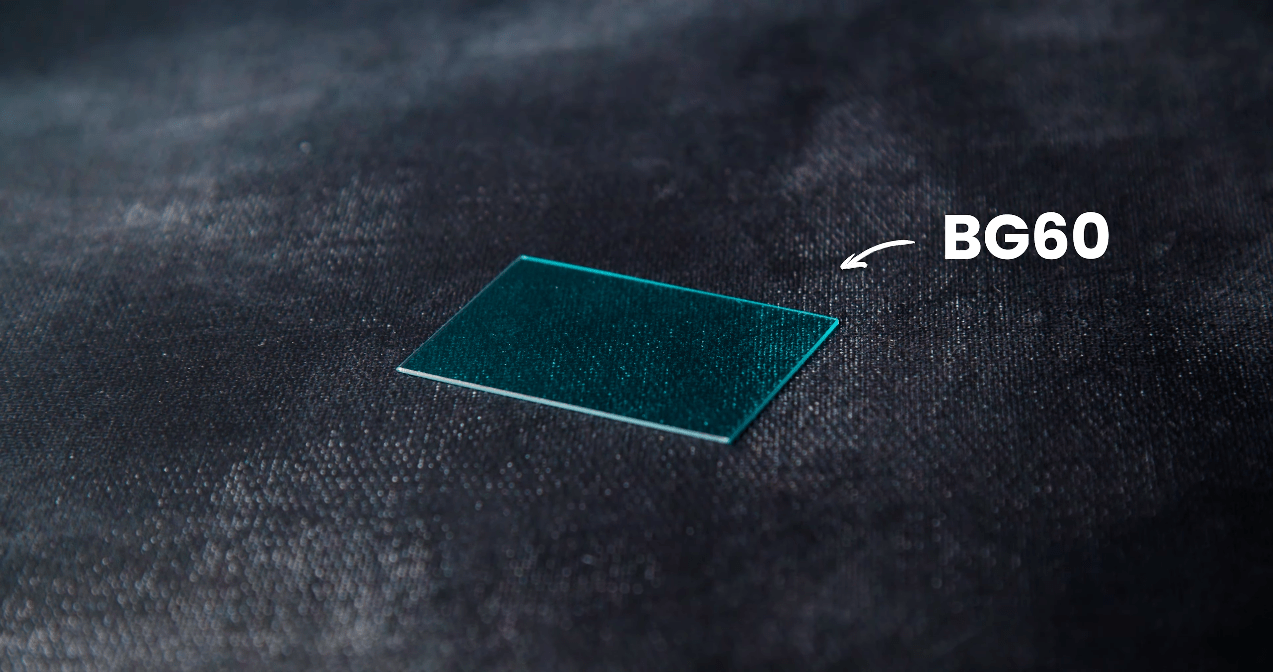

The second method is the glass equivalent of stainless steel, where the entire chemical composition of the glass is changed in a way that makes corrosion impossible. Schott was able to achieve this with BG60 & BG61. This glass will last indefinitely without oxidizing per Schott test reports.

The third option is to sandwhich the filter between two pieces of non corroding clear glass. The same way the coatings seal the glass, surrounding the filter with non corroding glass acts as a protective barrier from the elements preventing the blue/green filter from corroding. This is often done with the OLPF layer acting as a thick barrier however Leica and Blackmagic chose not to use an OLPF layer in order to increase sharpness. This is one of the reasons corrosion is an issue with these cameras.

When comparing the different methods while Schott BG60 & BG61 will last forever without corrosion, properly coated or environmentally sealed glass can last for decades depending on the environment. Your camera will most likely stop working before internal properly coated or sealed glass will begin to corrode

glass corrosion services

For Blackmagic users we offer a replacement or upgraded hot mirror that you can order and easily install yourself or send your camera in and we can install it for you. The filters have 16 layers of oxygen resistant coatings to prevent corrosion. Including Anti-Reflective (AR) coatings that increase transmission and reduce ghosting + hydrophobic coatings. We optimized this filter to provide the closest color match to the original Blackmagic UV/IR cutting hot mirror. On top of the corrosion issues, the original Blackmagic hot mirror does not consistently block all infrared light. This can cause color issues, most apparent in the shadows or black’s of your image. Black becomes polluted with red which can ruin your entire image. Our upgraded Blackmagic hot mirrors will block all infrared light solving this issue. You can also install our full-spectrum glass making your camera capable of capturing IR and UV light or install a dedicated infrared filter on certain Blackmagic cameras.

For Leica M9, M-E or S users we offer a service to replace the original hot mirror which is extremely prone to corrosion with either Schott BG39 or BG61. Schott BG61 will last indefinitely without oxidizing while Schott BG39 can become susceptible to corrosion if the coatings are scratched or worn off. That being said we offer a lifetime guarantee against corrosion for this service. Both filters feature anti-reflective and anti-smudge coatings. We can also replace the filter with our full-spectrum glass making it IR and UV compatible.

Understanding the science behind glass corrosion can help you understand how to prevent it. Even with properly coated glass it is important to keep your camera in a dry environment. Small packets of silica beads are a great way to ensure humidity levels don’t get too high. The beads absorb ambient moisture but reach capacity after 6-12 months. However they can be easily recharged to absorb moisture again by placing them in the oven or microwave. Another popular way to prevent corrosion is to store your camera in a humidity controlled dry cabinet. These can get a little pricey but are a great way to ensure your camera gear is never damaged by moisture in storage.

We hope you learned from this video and if you did consider subscribing to our newsletter for more photography and filmmaking content.