Sony ZV-E10 II Disassembly & Teardown

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

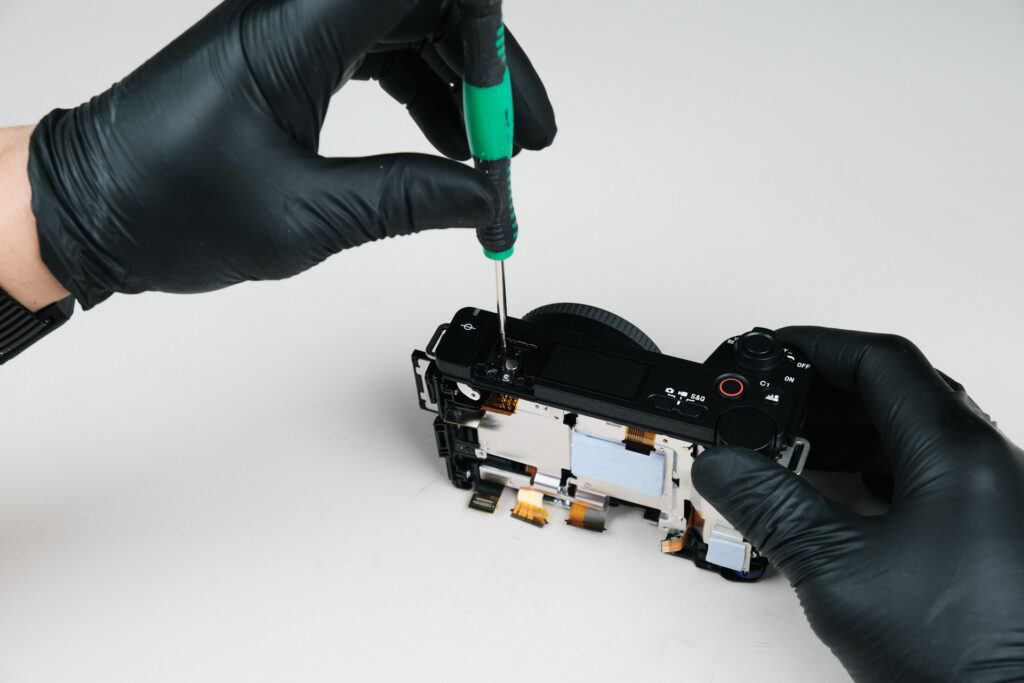

First, we went for the bottom of the ZV-E10 II, but we quickly realized that there was no dedicated baseplate, likely due to its incredibly small frame. We then started to remove screws surrounding the exterior of the camera—this included within the battery compartment, below the LCD screen, under the port covers, and beneath the leather skin.

We learned that the leather-skin of this camera isn’t like others. The “skin” on this camera are rigid plastic pieces covered in rubber, which are taped onto the camera. Since it isn’t really a flexible material, we had to use force—and great care—at the same time to peel it off the body.

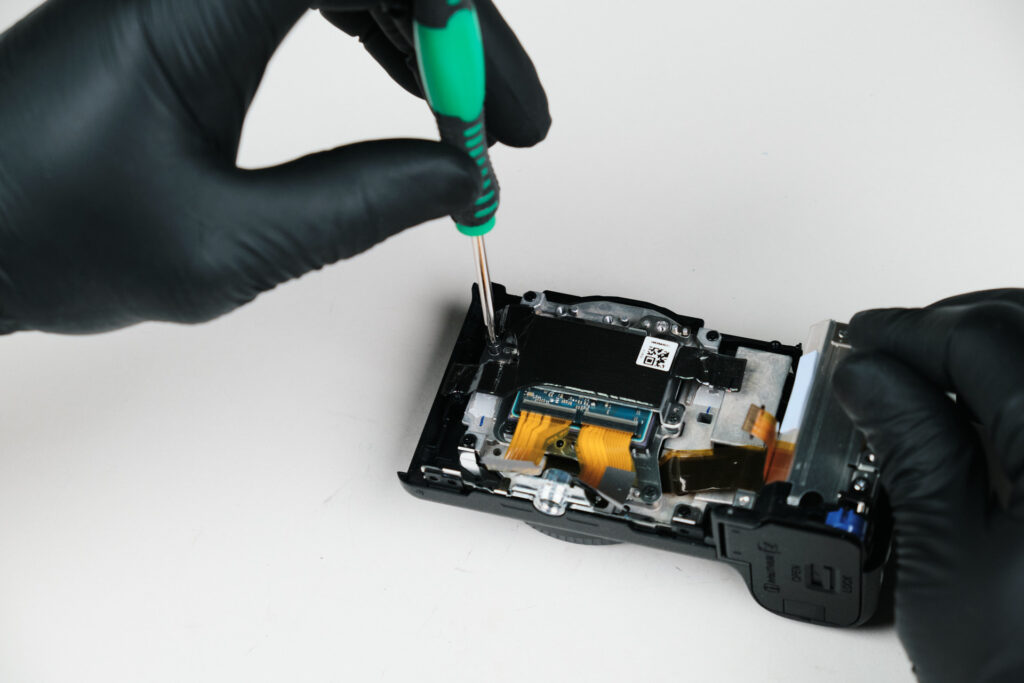

The backplate of the camera is connected by a single ribbon cable. Disconnecting it allowed us to detach the backplate from the camera body.

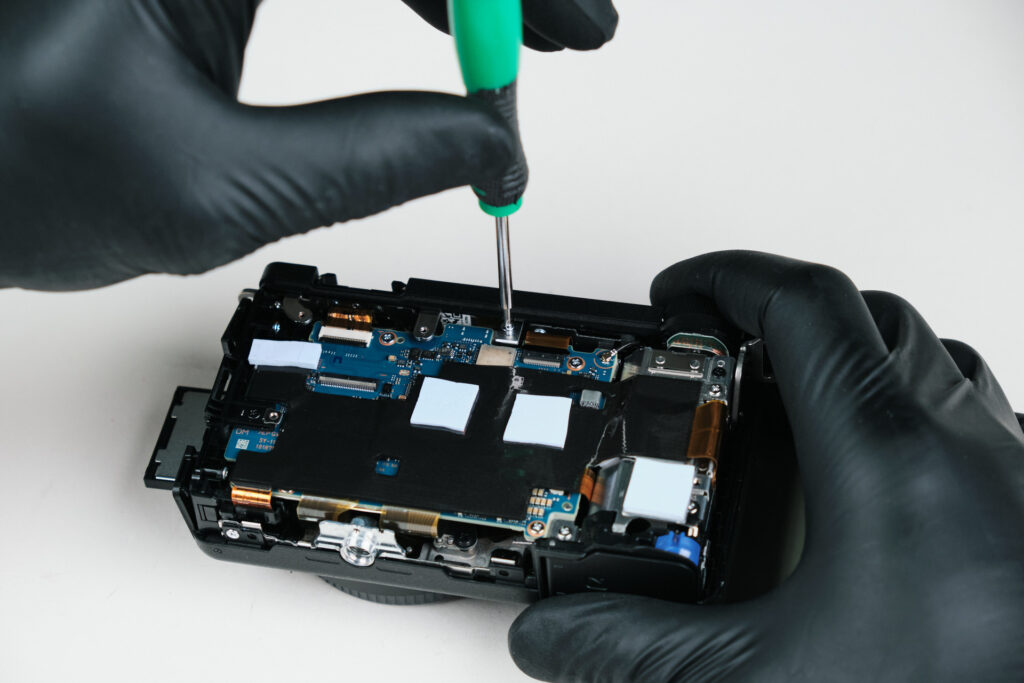

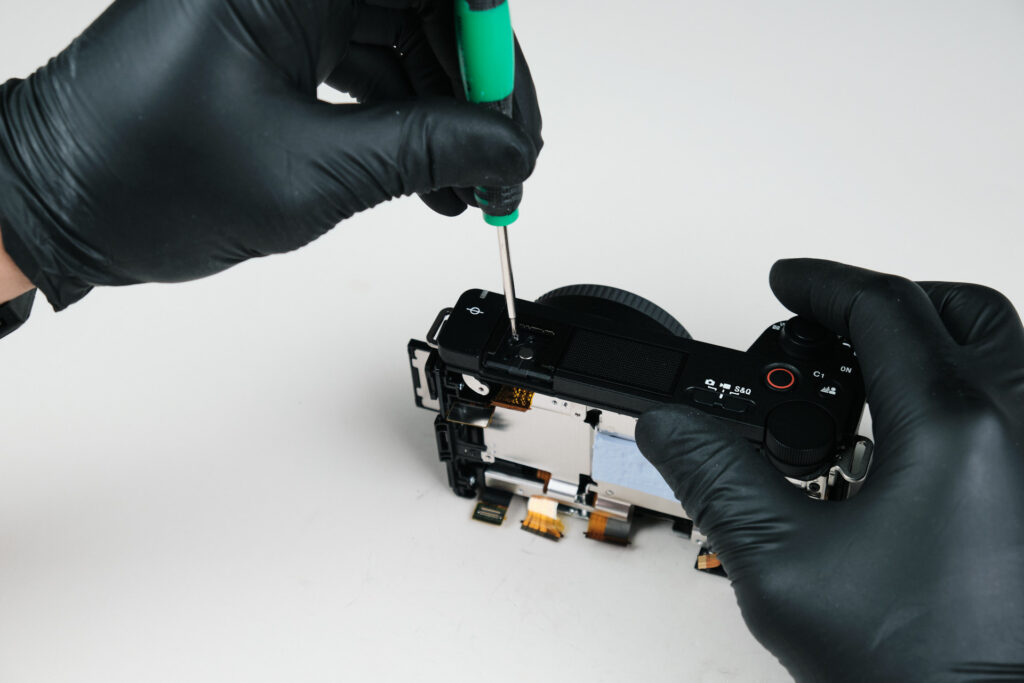

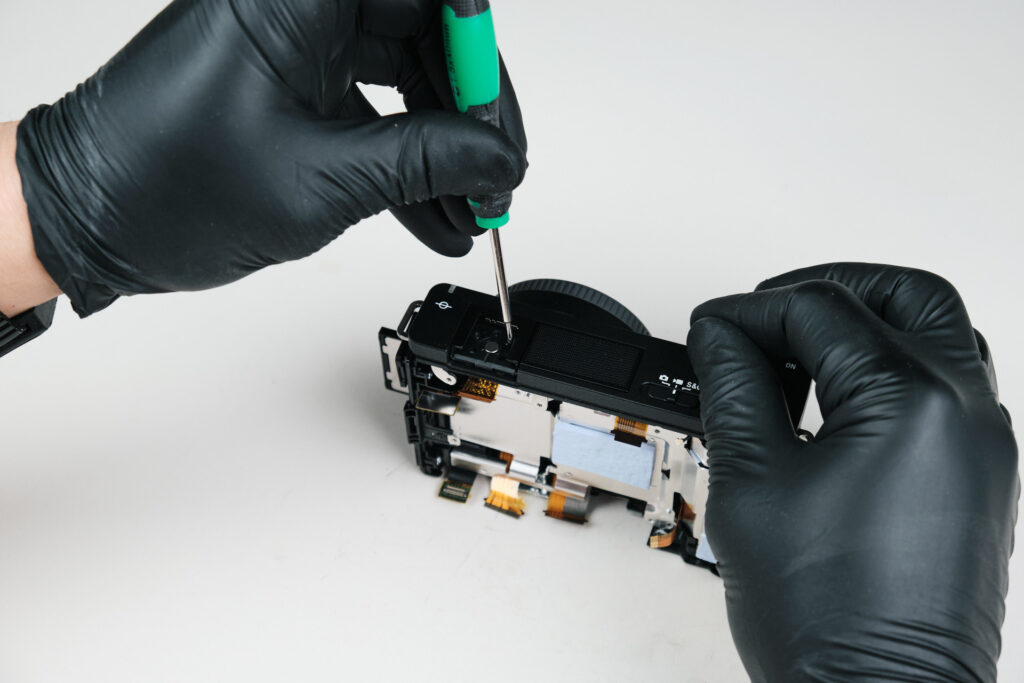

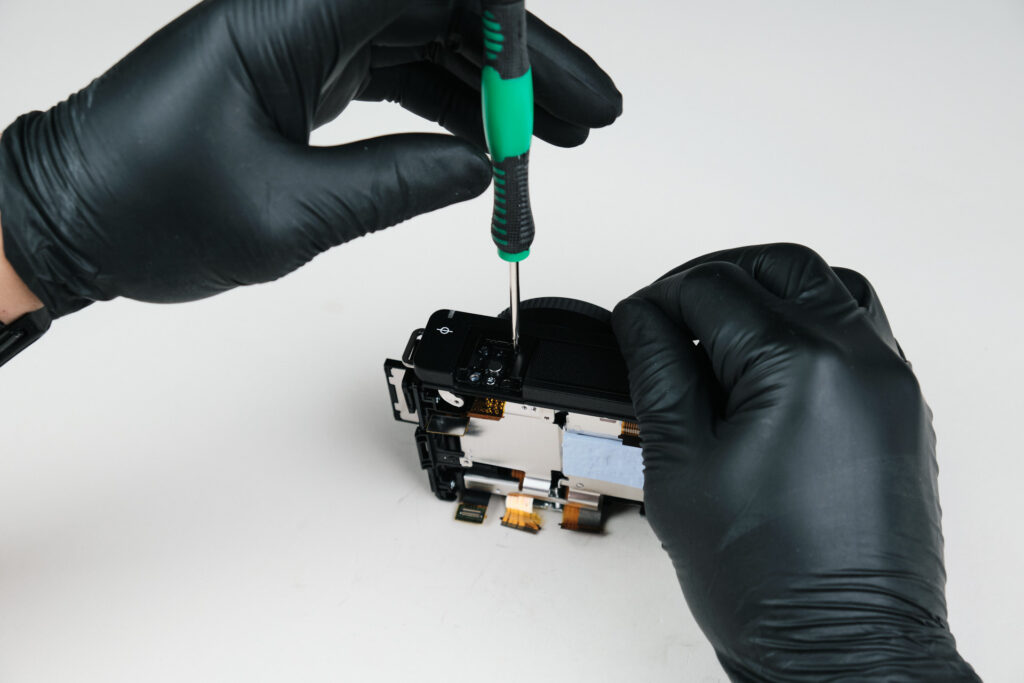

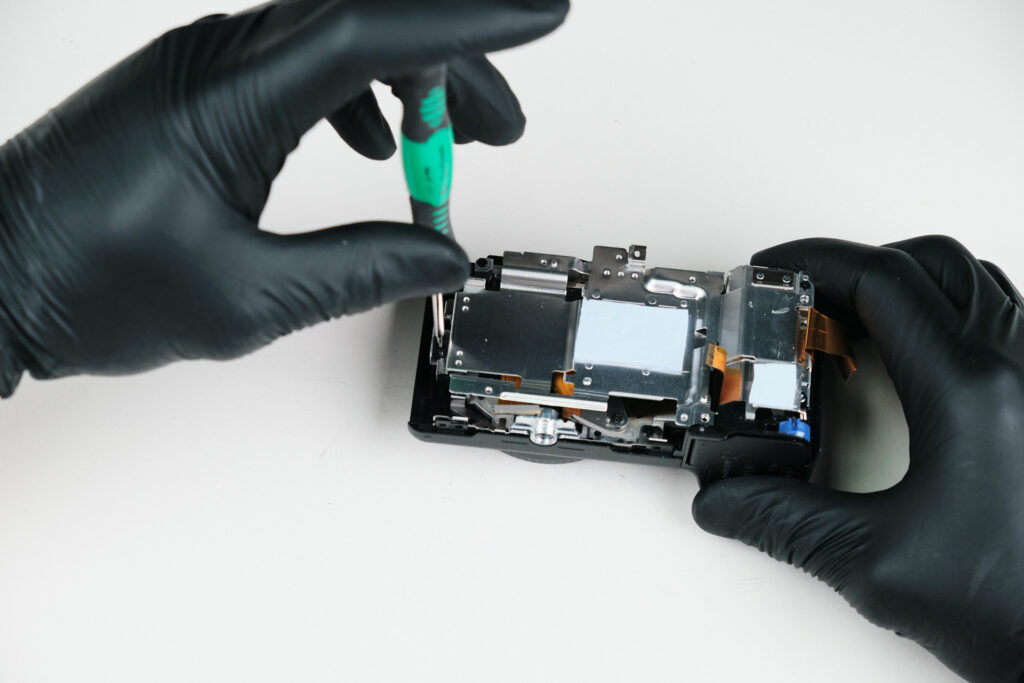

While Sony mirrorless cameras are generally easy to take a part, the ZV-E10 II was another one of those cases where the new design had us meandering and figuring out things along the way. It seemed that the circuitboard could be removed at this moment, but we also had to consider the parts that we haven’t removed yet, namely the the top plate of the camera. Here, we removed several deep screws, detached some ribbon cables, and one wire. Removing these parts did not allow us to detach the top panel of the camera.

At this point, we were looking for more parts to remove that would let us detach the top panel. Earlier, we peeked under the righthand plastic and leatherskin covering to remove a screw, so here we decided to fully remove it. This revealed two more screws on the exterior of the camera frame. We also removed one screw towards the bottom of the camera.

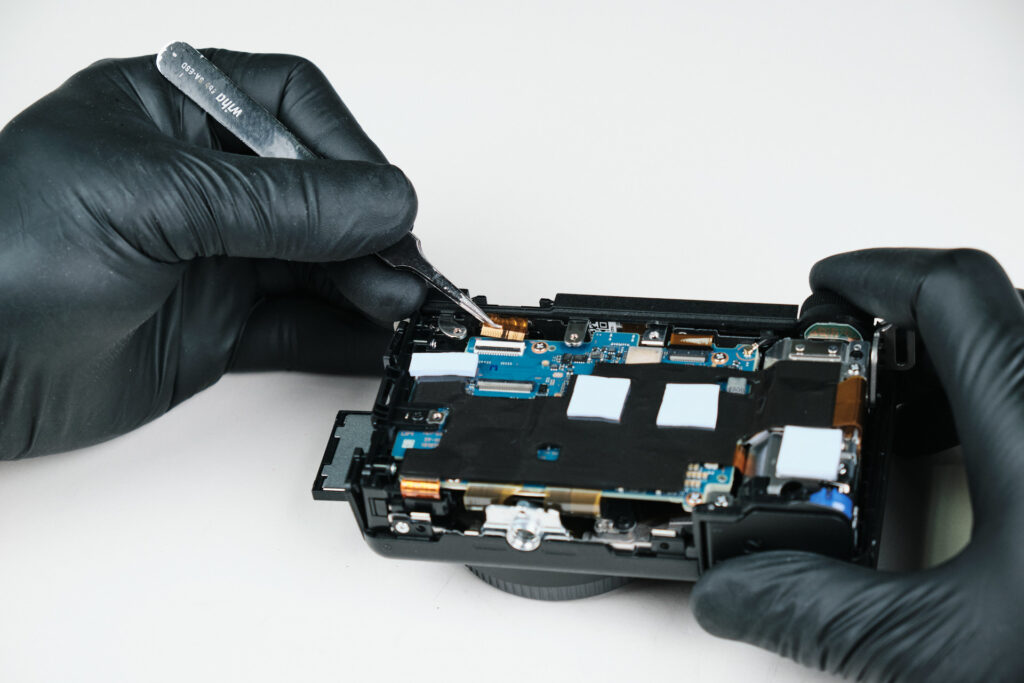

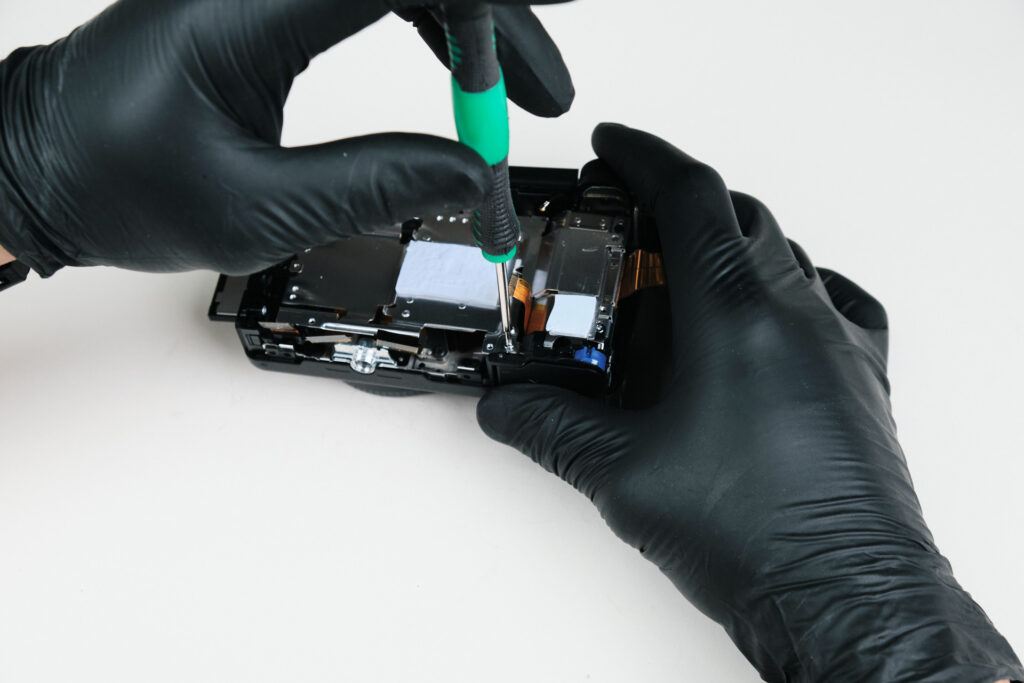

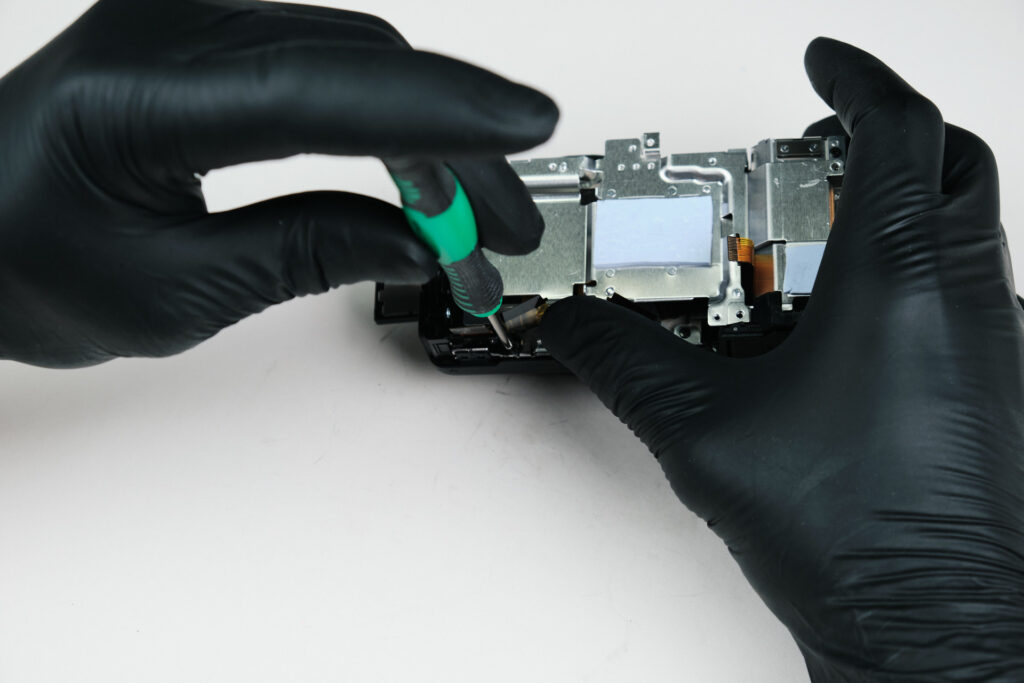

Moving back to the internal area, we missed one more screw deep within the camera body, and we removed the heat transfer tape before moving on to the circuitboard.

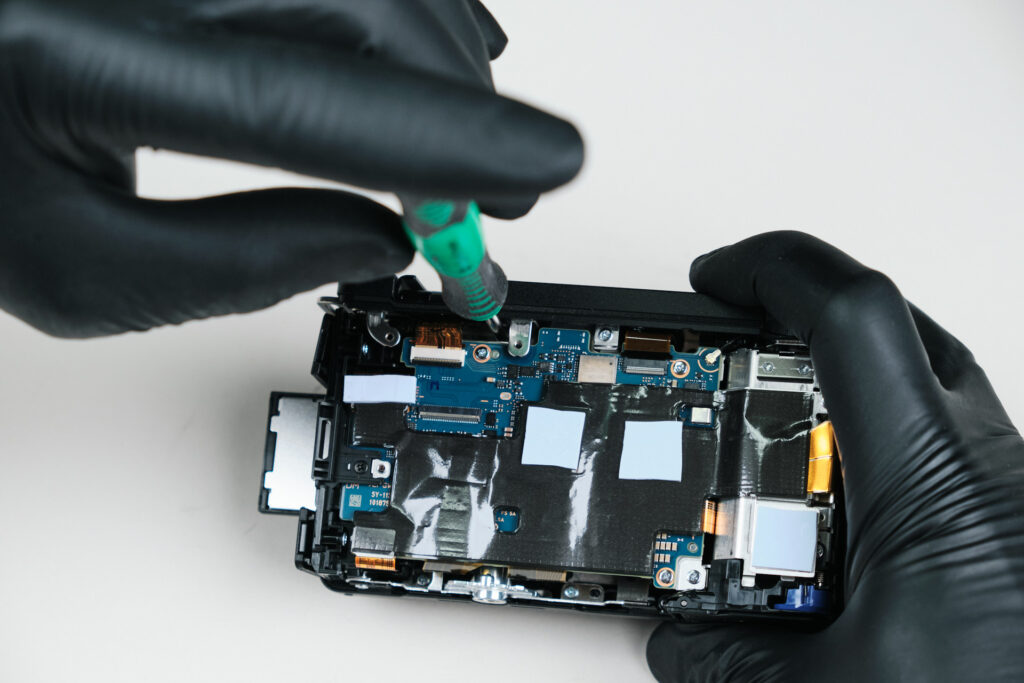

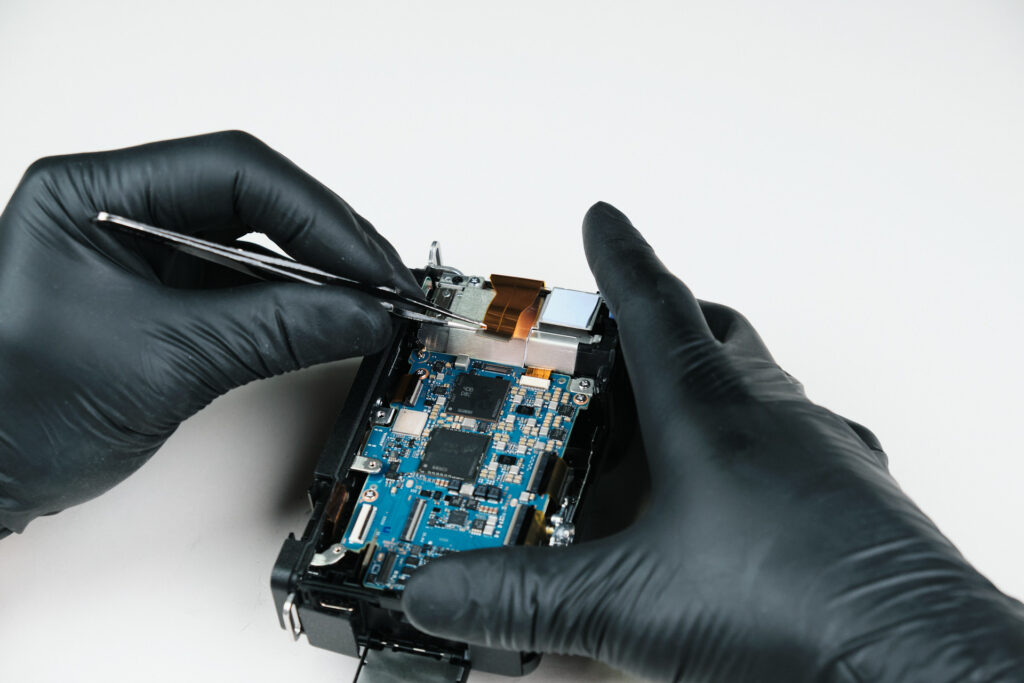

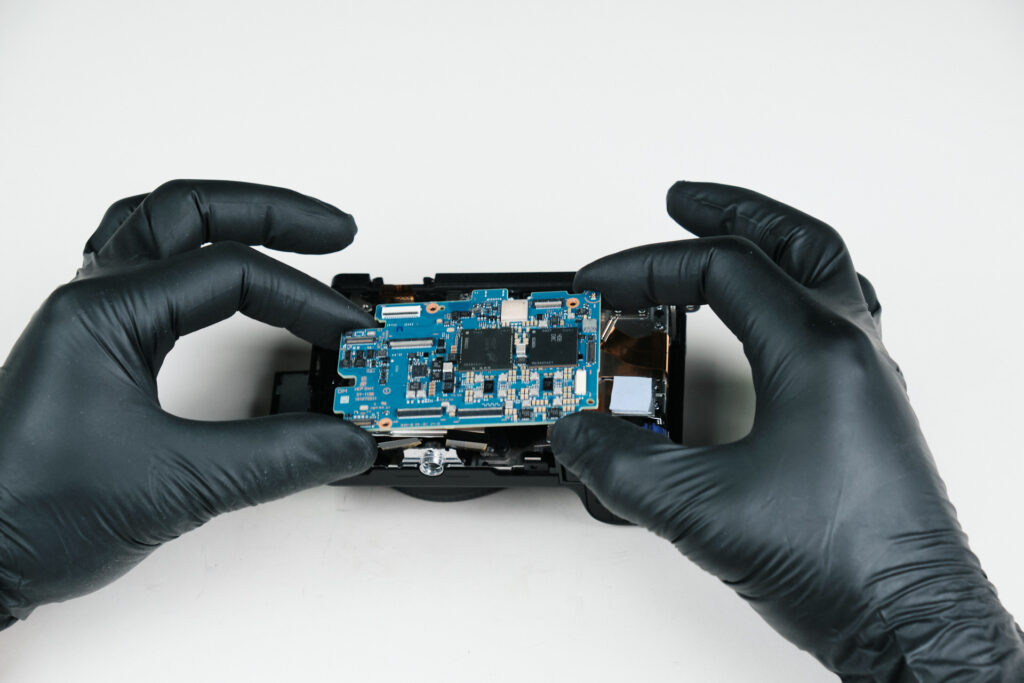

We detached several ribbon cables from the circuitboard.

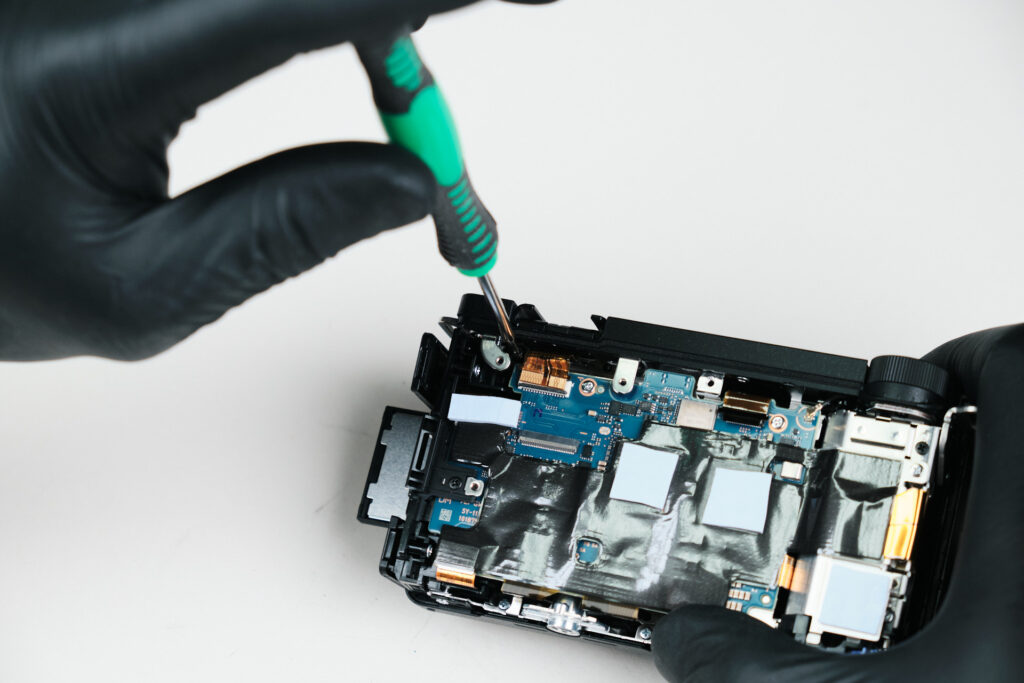

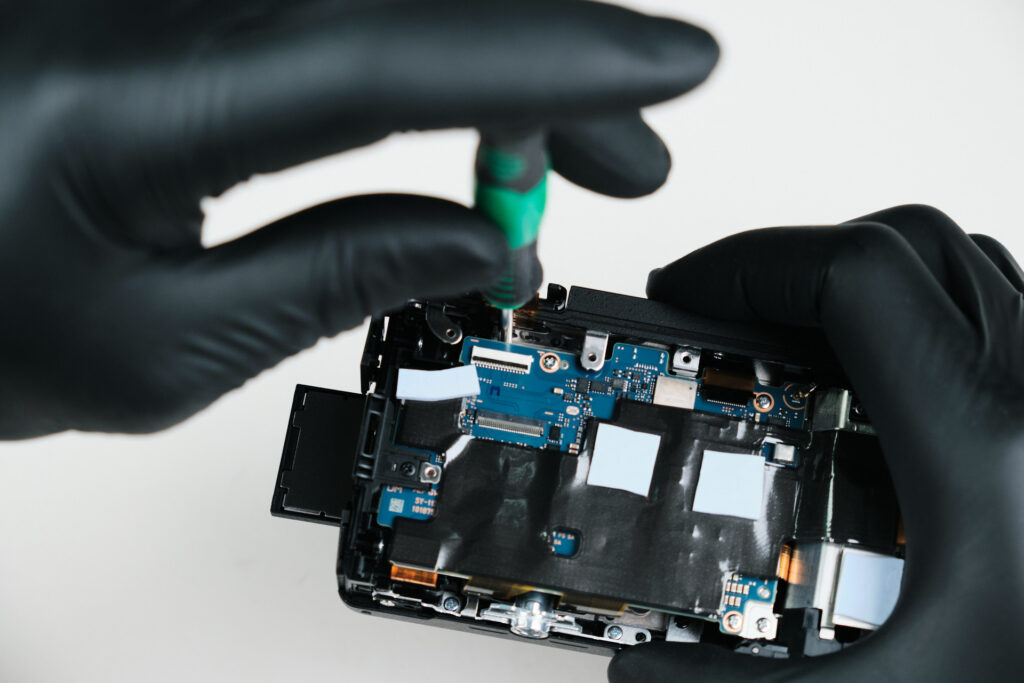

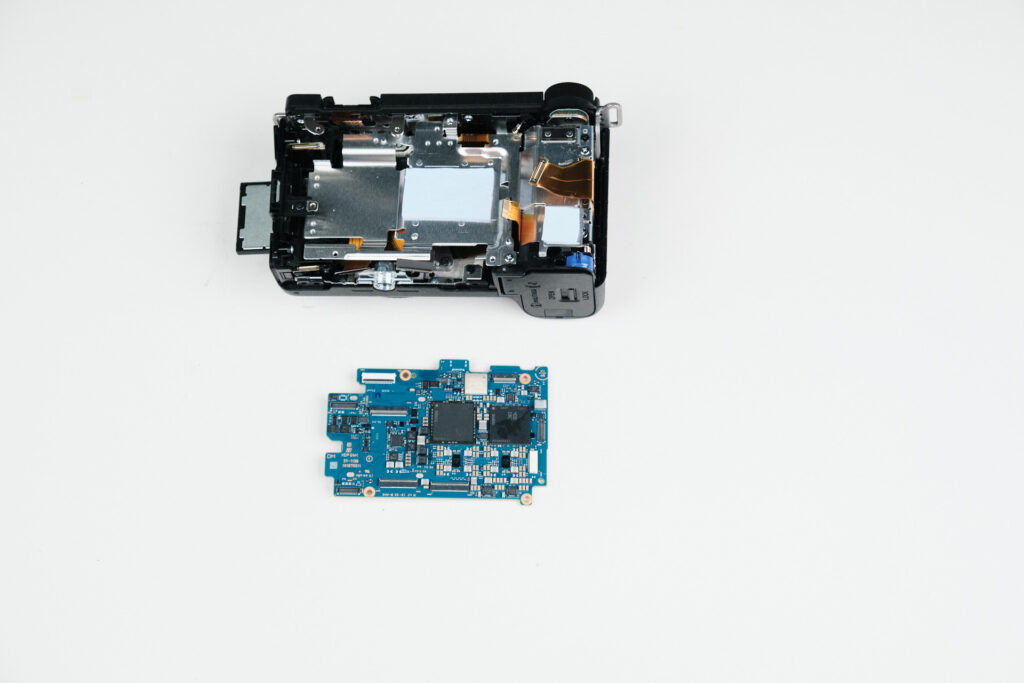

The last thing we needed to do to remove the circuitboard was remove the screws around its perimeter. There were four screws altogether. Removing this allowed us to lift the circuitboard from the camera body.

The Sony ZV-E10 II’s circuitboard.

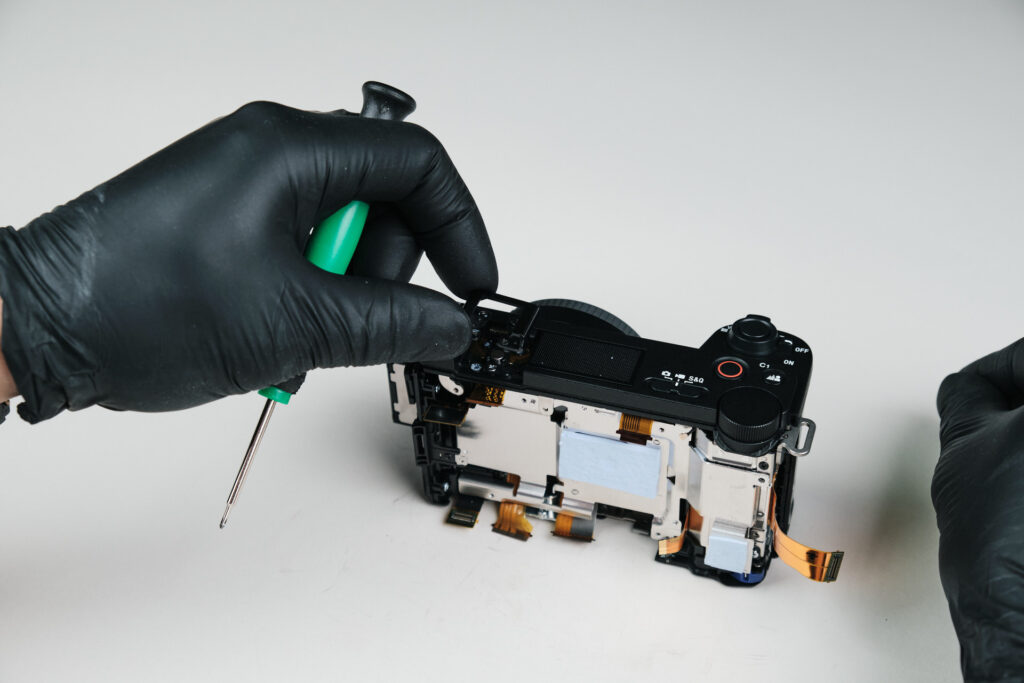

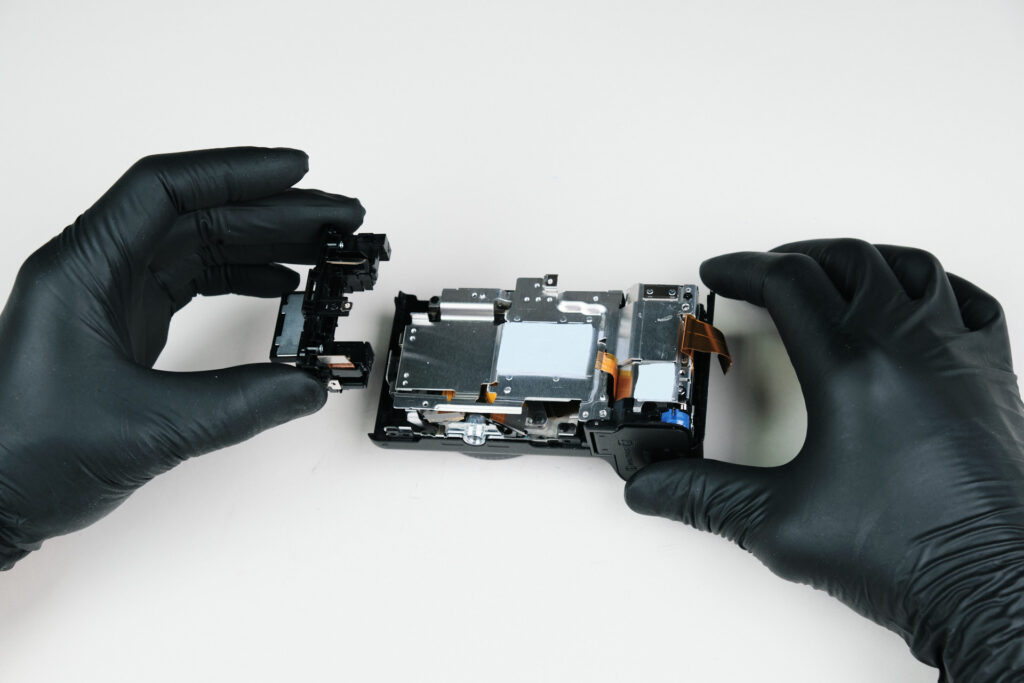

We removed many screws around the exterior and within the interior of the camera, yet we still weren’t able to remove the top panel. We realized that the last part to remove lied within the hot shoe mount. Removing the screws here (along with the screws surrounding the camera body) led to the removal of the top panel.

The last thing we needed to remove before we could get to the camera sensor was the main bracket. One of the screws held down a plastic piece which doubled as the port side cover. Aside from that, there were only a few screws that held down the main bracket.

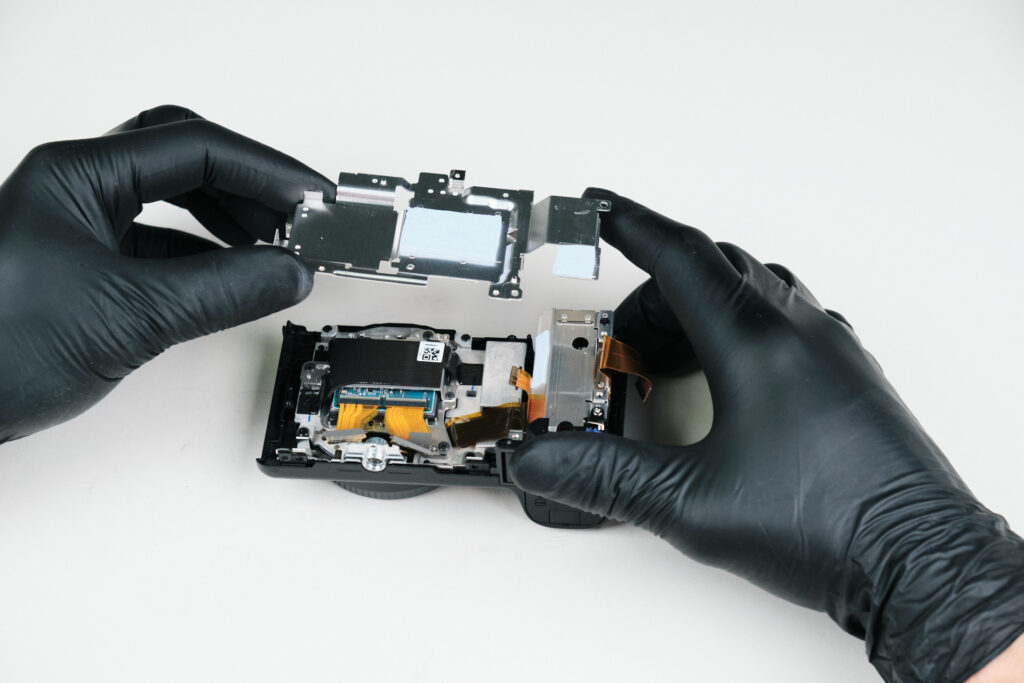

With the main bracket removed, we finally reached the camera sensor. We were going to remove the heat transfer tape, but we quickly realized that the heat transfer tape didn’t need to be removed at all. The sensor was only held down by three screws.

The camera sensor of the Sony EV-10 II. The sensor is APS-C sized.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.